Welcome to our Alphatech Engineers!

Call us 9:00am - 6:00pm

+91 9930469880

Monday to Friday

9:00am - 6:00pm

E-mail us

info@alphatecheng.com

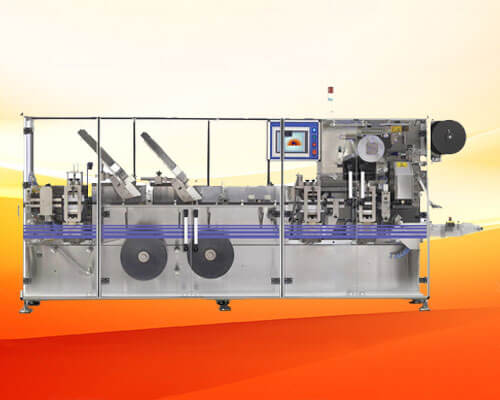

Blister Packing Machine

Blister packing machine (BPM) is suitable for both the Cold Forming and thermo Forming blisters. The machine is suitable for Large batches.

A-44EXL Flat Forming Flat Sealing intermittent running, having Format area 230 x 140mm.The machine is suitable for Large batches Base Materials : PVC/PVC-PVDC/ACCLAR/TRIPLEX/PP/ALU-ALU (OPA). Lidding Material : Aluminium with Heat Sealable Lacqure Coating.

We are leading manufacturer, supplier & exporter of Blister packing machine in Mumbai, India.Salient Features of Blister Packing machine (BPM):

- Packing speed : 40Cycles/Min for Thermo-forming 35Cycles/Min for Cold-forming

- Feeding system : Auto feeding system by PLC logic with Pneumatic Combination

- Servo Drive Indexing: Servo web indexing by rigid PLC logic

- Operator Interface: User friendly MMI Touch screen

- Pneumatic Operations: FESTO make fast responsive, Oil free, minimum wear and tear, easy maintenance and universal availability of brought out.

Tech Specs: A-44EXL

- Base film Width.

- Blister Foil Thick

- Reel Dia

- Sealing Foil Thick

- Sealing Foil Width

- Pack Length

- Pack Width

- Forming Depth

- Machine Speed

- Floor Space Approx

Tablets / Capsule Blister Packing machine

The machine is thermo forming standard basic machine PVC ALU Rotary vacuum principal, thermo forming standard basic machine having format area 210 x 100mm. The machine is suitable for medium and large batches.

Salient Features

- Rotary vacuum principal, thermo forming machine having format area of 210x100mm. The machine is designed for deep blistering to accommodate Ampoules, Vials etc..

- Average Speed 35 strokes/Min.

- The rate of production largely depends on the size of formulations

Technical Specification IPEC-A-240+

- PVC Base Film Width Max. 210 mm

- PVC Film Thickness Max. 0.2- 0.4 mm

- PVC Reel Dia. Max. 440 mm

- Aluminum Foil Width Max. 206 mm

- Aluminum Foil Thickness Max. 0.02-0.03 mm

- Aluminum Foil Dia. Max. 210 mm

- Total Forming Area. MAX 210 x 102 mm. MIN 210 x 25 mm

- Pack Length. 200 mm

- Pack Length. 200 mm

- Forming Depth. 16 mm

- Out Put. 240 Packs / Min (2400 Blisters / Min)

- Floor Space Approx. L: 3100mm. W: 1100mm. H: 2000 mm.

- Net Weight Approx. 1150 kgs.

Ampoule Blister Carton Link Line

This product, an auto assembly line, is used for small round bottle printing, tray forming, feeding in tray, cartooning packing. The structure is compact and convenient operation. It integrates the photoelectron, mechanics, electric and pneumatic, controlled by PLC, driven by servo motor, automatically folds leaflet and finish cartooning packing. It adopts sensor monitoring to coordinate the operation of each section.

If any error takes place, it can stop automatically and display the report so as to solve them on time. With advanced detection system, the line can detect and recognize the empty or lack packing tray or lack packing carton to achieve 100% finished product. The tray mould can be made according to customer’s requirement.

Technical Specification

- Cutting Frequency (Times/min) 10-30

- Capacity (Box/min) 50-100

- Max Forming Areas And Depth (mm) 340×150×26

- Travel Range (mm) 40-160 (Can Be Lengthened To 180mm As User's Requirements)

- Air Pressure(Mpa) 0.5-0.7

- Volume of Air Consumption 20m3/h Pressure: 0.5-0.7 Mpa

- Total Power 380V/220V 50Hz 8kw

- Main Motor Power (KW) 3

- PVC Hard Pieces(mm) 0.15-0.5×350

- PTP Aluminum Foil (mm) 0.02-0.035×350

- Dialysis Paper(mm) 50-100g×350

- Carton Specification Weight: 250-350g/m2

- Max. size: 200x80x50mm

- Min. size: 70x30x15mm

- Leaflet Paper weight : 55-65g/m2

- Max. size: 250x190mm (L×W)

- Min. size: 100x100mm (L×W)

- Mould Cooling Tap Water Or Circulating Water

- Overall Dimensions (mm) 7000×1350×1700 (L×W×H)

- Weight (kg) 3500

Automatic Cartoning Machine

Alphatech Engineers Automatic Cartoning machine applies to the encase packing of blisters, vials, cosmetics, poker and similar stuff. This machine can fold leaflet, open carton and insert stuff with leaflet into cartons, printing batch number and close carton automatically.

This machine adopts horizontal configuration, PLC control system, photocell detector installed in each station enables stable running. If there is anything wrong with the machine, it can stop automatically and display the troubles so as to solve them in due time. The machine can be singly used or linked with blister packing machine to form a production line.

Features

- Carton Weight: 250-350g/m2

- Max. size: 200x90x60mm

- Min. size: 70x20x15mm

- Operation manual

- Paper weight :55-65g/m2

- Max. size: 250x190mm(L×W)

- Min. size: 100x100mm(L×W)

- Overall dimension: 3100×1350×1450 (L×W×H)

- Weight :1200kg

- Power supply: AC 380V 50Hz Triphase 4 lines

- Total power :1.5kwCapacity: 30-100 Box/min

- Folder speed :50-90 Box/min

- Air consumption :20m3/h (pressure 0.5-0.7mpa)

- Stop automatically if the packed product does not go to the right position.

- Stop automatically if there is no carton, continues lack of instruction manual or no product.

- It is convenient to change different specification.

- Overloading protecting for main drive.

- PLC will automatically display the speed and count the finished product.

- PLC will automatically display trouble, stop the machine and alarm, and display the operation and maintaining ways.

- Automatically eliminate the plate that lacks of packed matter or operation manual.

1ml, 2ml & 5ml Ampoules Blister Packing Machine

The PEW-RP-MACAV1 is suitable to Blister Pack 1ml, 2ml and 5ml Ampoules. The machine has a unique cantilever design with frontal format part accessibility in a modular balcony type construction. The basic machine comprises of mild steel chassis with SS 304 frames welded and bolted to form a rigid frame device structure on which various modular stations are mounted in balcony design (from GMP compliance and pharmaceutical sanitation standards).

Floor Dimensions

- Machine Width 1180+/ - 2%

- Machine Height 1920+/ - 2%

- Machine Length 3870+ / - 2%

Salient Features:

A base film draw of station cantilever to the outside on the base of the machine allowing easy operator accessibility. The loop sensor to indicate the end of forming reel. Pre-heating station comprising Teflon coated pre-heating platen used for heating the thermo formable base film.

- Forming station ? Pneumatically activated plug assist for deep draw cavities in thermo formable material.

- Special ampoule shuttle feeder to feed the ampoules gently into the formed web.

- Lidding foil: draw of loop sensors to indicate lidding foil exhaust.

- Batch code printing using mechanical and Pneumatic control for printing batch information on the lidding film.

- Sealing station

- Seal web guide to cool the hot sealed web to ensure uniform sealing.

- Linear indexing: servo assisted linear indexing for ensuring accurate indexing of the sealed web without leakages.

- Punching tool: This shears of the blister form the web.

- Trim re-winder which collects the trim after punching externally to the machine ensuring no waste within the machine area.

- An outfeed conveyor to convey the punch blister parallel to the web transport direction.

- PLC to sequence and synchronise the various operations of the machine.

Technical Specification:

- Max Machine Speed 20-25 Cycles per minute

- Max Forming Area 222mmX175mm

- Min Pack Size 40x60mm

- Optimum Forming Depth 25mm

- Max Reel Diameter 440 mm

- Max Lidding Foil 220 mm

- Max Core Diameter 70-76mm

- Net Weight Approx 2500 KG

Tablets / Capsule Blister Packing Machine

The PEW-RP-Roto2 is an automatic Blister packaging machine utilized for packing of Tablets & Capsules in blister packs. The machine has got Pack Pick and Place system having integrated, trim and rejected Blister Collector. This machine can be linked to downstream automation like Collator and / or Cartoner. The machine includes the out feed conveyor for the link-up.

Salient Features:

- A freely programmable logic controller, interfaced with a digital display unit (MAN-MACHINE INTERFACE), controls the multiple functions on the machine

- All the operational controls and sequences of the machine are arranged by Man-Machine Interface mounted conveniently located in front of the machine and rotary encoder, which determines the positional accuracy of the machine with the feedback.

- All the parametrical changes can be affected with controls through the MMI, which has multiple level of password protection.

- The machine equipped with basic drive unit controlled by an AC frequency Converter

- Products to be packed on the machine are specifically pharmaceutical products such as Tablets and Capsules.

- Different types of products to be fed in to the blister formed cavities on the formed web over the web guide track at the feeding zone.

- The output capacity of the machine depends upon the product characteristics meats size and shape of the products and on the type of feeding device.

Technical Specification:

- Max. Machine Speed for Thermoform (Product & Layout Specific)

- Maximum Output :360 Blister/min.

- Max. Forming Area :220 x 110mm

- Min. Pack Size :30 x 70mm

- Optimum Forming Depth :10mm

- Max Reel Diameter (Base Foil) :440mm

- Max Reel Diameter (Lid Foil) :210 mm

- Max. Base Foil Width :230 mm

- Max. Lidding Foil width :226 mm

- Max. Core Diameter :70-76 mm

- Machine dimensions

- Machine Width 1190 mm + 2%

- Machine Height 2020 mm + 2%

- Machine Length 2775 mm + 2%

- Net weight Approx 1800 kgs.

Tablet Capsule Blister Packing Machine

The IPEC-RP-240 is an automatic Blister Packaging machine utilized for packaging of the tablets, capsules in a blister pack. This is a machine with continuous operations of forming station, feeding station, sealing station and printing station. Whereas punching station is of intermittent nature. Product capacity of the machine depends on the product characteristics, pack layout and on type of feeding device

Salient Features:

- PVC film is generally used as base film and Aluminum foil with heat sealable VMCH coating as lidding film.

- Batch code printer, Inspection Camera and Inline perforator are the accessories, which can be mounted on the machine.

- The blister cavities are formed on the PVC/PVDC film web by vacuum processes.

- This blister formed web moves over the web guide track and at this station the products are fed into the individual cavities.

- The formed web along with the tablet or capsules moves towards a sealing station, where it is fused to the aluminum foil, which is drawn from an aluminum reel – feed station

- The punching tool punches out the specified pack, which is transferred to the out feed conveyor.

- Products to be packed on the machine are specifically pharmaceutical products such as Tablets and Capsules. Different type of products can be fed into the blister formed cavities on the formed web over the web guide track at the feeding zone

Technical Specification:

- Max. Machine Speed (Packs)4.5-5.5 meters/min{240 packs per minute}

- Max. Forming Area 110 x 210mm

- Max. Forming Area 30 x 140mm

- Optimum Forming Depth 10mm

- Max Reel Diameter 440mm

- Max. Lidding Foil 210 mm

- Max. Core Diameter 70mm Floor Space

- Machine Width 925 mm

- Machine Height 1750 mm

- Machine Length 2900 mm

Vial Blister Packing Machine

Suitable for ampoule, vial, oral liquid and other small round bottle automatic printing, tray forming and feeding in tray. This machine is an improved product innovated by our company that incorporates pneumatic-photo-electro-mechanic, controlled by PLC and man-machine interface operation. It meets packing requirement of small round bottle as ampoule for automatic printing, tray forming, feeding and cutting. It is featured by compact construction and convenient operation.

Model:

- Model PEW-IDPB250/PEW-IDPB320/PEW-IDPB350

- Cutting Frequency (times/min) :10-30/10-30/10-30

- Production Capacity (pcs/h) :12000-30000/13000-35000/15000-38000

- Max. forming area and depth (mm)240(310/340)×140×26(Standard depth: 14

- Travel Range (mm) :40-150 (Can be lengthened to 180mm as user's requirements)

- Air Pressure (Mpa) :0.4-0.6

- Air Supply :=0.35m3/min

- Total Power :380V/220V 50Hz 6.2kw

- Main Motor Power (kw) :1.5

- PVC Sheet (mm) :0.25-0.5×250 (320/350)

- PTP Aluminum Foil (mm) :0.02-0.035×250 (350)

- Dialysis Paper (mm) :50-100g×250 (350)

- Mould Cooling :Tap Water Or Circulating Water

- Weight (kg) :1600/1900/2100

Features:

- Automatic production line of up and lower heating, positive press forming (tray forming), printing, automatic feeding (feed in tray) and cutting.

- Equipment with mechanism checking device, eject empty or lack packing tray automatically. Blister forming, heat-sealing, lot number embossing, avulsion line impressing and cutting etc all adopt gear mandrel orientation, each can move freely in the mandrel when rotating the hand wheel, and the machine equipped with a staff gauge and tightening nuts for calibration and orientation.

- It can line with labeling machine in front and cartooning machine in back part, carry out the whole automatic production line.

- Main transmission part adopts parallel axis and bevel wheel speed reducer. Forming, heat-sealing and impressing moulds adopt bolt orientating which leads to precise orientation, easy to change mould and material saving